ASTM – A500 grade B and C is the standard specification for cold-formed carbon steel welded tube. Specifically, it’s hot rolled steel tubing with electric resistance weld (HREW). Commonly called H.S.S Tubes (Hollow Structural Steel).

Thanks to its high physical capacities and a very large variety of sizes, ASTM – A500 grade B and C H.S.S. tubes are used for structural purposes by our manufacturing customers in various fields of activity.

| Grade B | Grade C | |

|---|---|---|

| Yield strength | 42 000 PSI | 50 000 PSI |

| Tensile strength | 58 000 PSI | 62 000 PSI |

| Thickness tolerance | ± 10% from the wall | ± 10% from the wall |

ASTM A500 Steel Tubing is a benchmark specification for both cold-formed welded and seamless carbon steel structural tubing. Known for its strength and flexibility, it serves as a foundational component in numerous structural applications.

This steel tubing is available in two grades, Grade B and Grade C, each with properties that cater to different needs. Grade B has a minimum yield strength of 42,000 psi, making it suitable for heavy-duty applications. Grade C, with a minimum yield strength of 46,000 psi, offers even greater strength and structural support.

ASTM A500 steel possesses properties that make it a preferred material in the fabrication of various structural applications. With distinct grades, Grade B and Grade C, this steel tubing offers different levels of strength and resilience.

Both grades exhibit flexibility and durability, contributing to reliability across various applications.

ASTM A500 steel tubing is widely used in diverse industries due to its strength, flexibility, and weight. Grade B tubing, with its favorable strength-to-weight ratio, is often employed in construction projects where weight considerations are important.

Grade C tubing, known for its higher strength, is favored for more demanding structural applications. Additionally, its specified wall thickness supports structural integrity, making it suitable for skyscrapers, bridges, and large industrial projects.

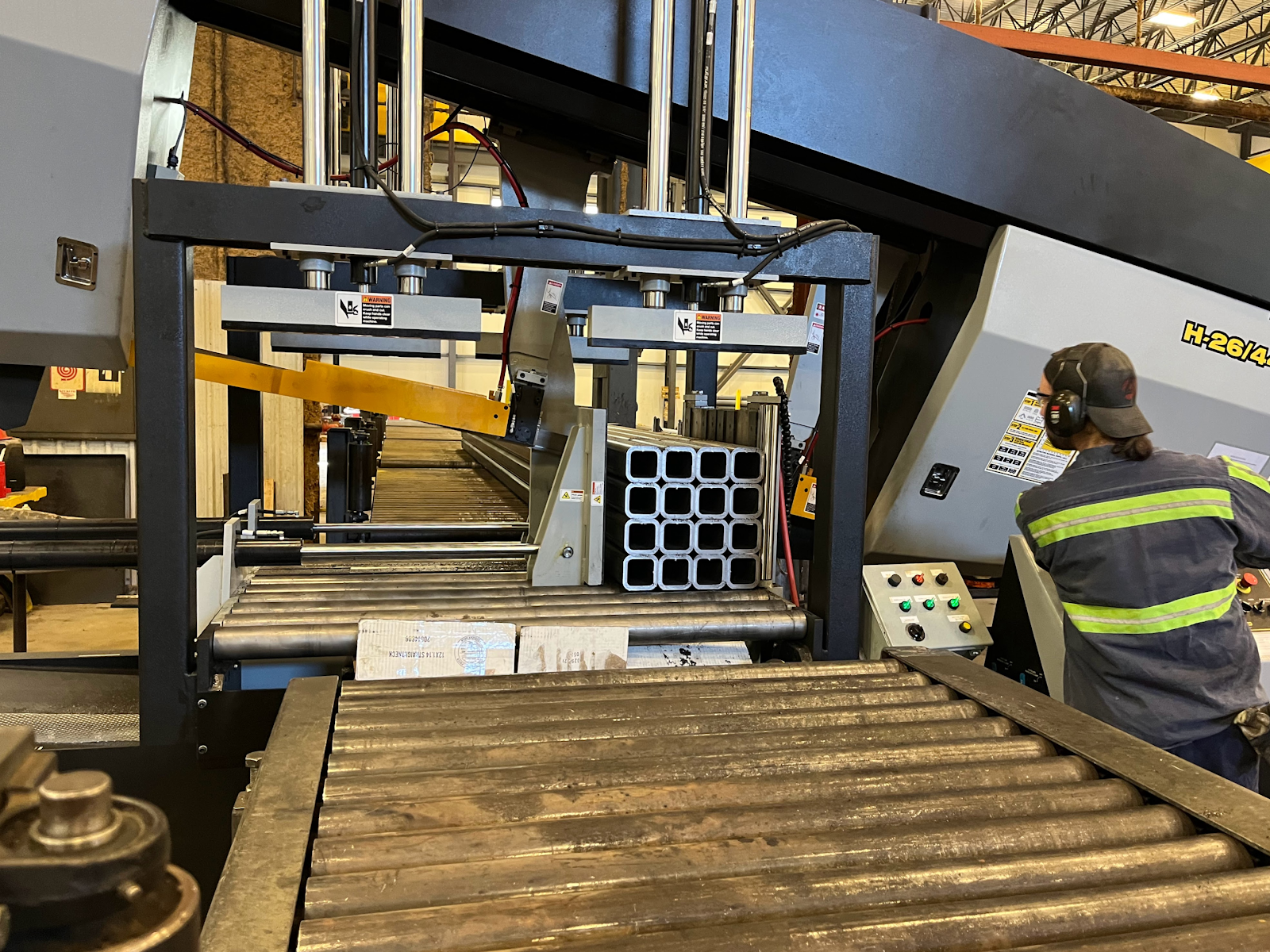

Electric resistance welding (ERW) is a key process in the manufacturing of ASTM A500 steel tubing. At Altitube Steel, we recognize the importance of this welding method in contributing to the structural integrity and quality of our tubing products.

ERW involves applying electrical current and pressure to join the edges of steel strips, forming a continuous seam along the length and thickness of the tubing. This process results in welded joints that are strong and reliable, suitable for various structural applications.

A500 Grade B and Grade C tubing are widely used across diverse industries due to their strength and versatility.

Both grades ensure durability and reliability in structural engineering applications.

At Altitube Steel, we understand the importance of selecting the right steel tubing for your project. This is why we offer a comprehensive comparison between ASTM A500 and other common types of steel tubing.

ASTM A500 steel tubing typically has higher tensile strength and yield strength compared to many other varieties. This makes it suitable for structural applications where durability and strength are important. However there are other grades with higher tensile and yield strengh as, CSA G40.21 350W or ASTM A500 modified. ASTM A500 also performs well in terms of ductility, allowing it to withstand high levels of stress without fracturing.

Unlike some other steel grades, ASTM A500 is manufactured to meet specific mechanical properties rather than chemical composition, promoting consistent performance across various applications.

ASTM A500 tubing distinguishes itself from other steel tubing with its:

Its superior ductility enables it to withstand elevated stress levels without fracturing, helping to ensure long-term structural integrity. Unlike some steel tubing shapes and types, A500 is engineered to meet specific mechanical properties, promoting reliability and uniform performance across various applications.

Altitube Steel is committed to delivering high-quality ASTM A500 steel tubing that complies with industry safety and quality regulations. Our ASTM A500 steel tubing meets the standards set by ASTM International, known for their rigorous quality and safety measures.

This means our tubing has undergone extensive testing for yield strength, tensile strength, and elongation to help ensure it can handle the demands of various applications. We also adhere to safety regulations, promoting the safe use of our products in construction and industrial environments.