Pros and Cons of Carbon Steel Pipes

Advantages of Using Carbon Steel Pipes

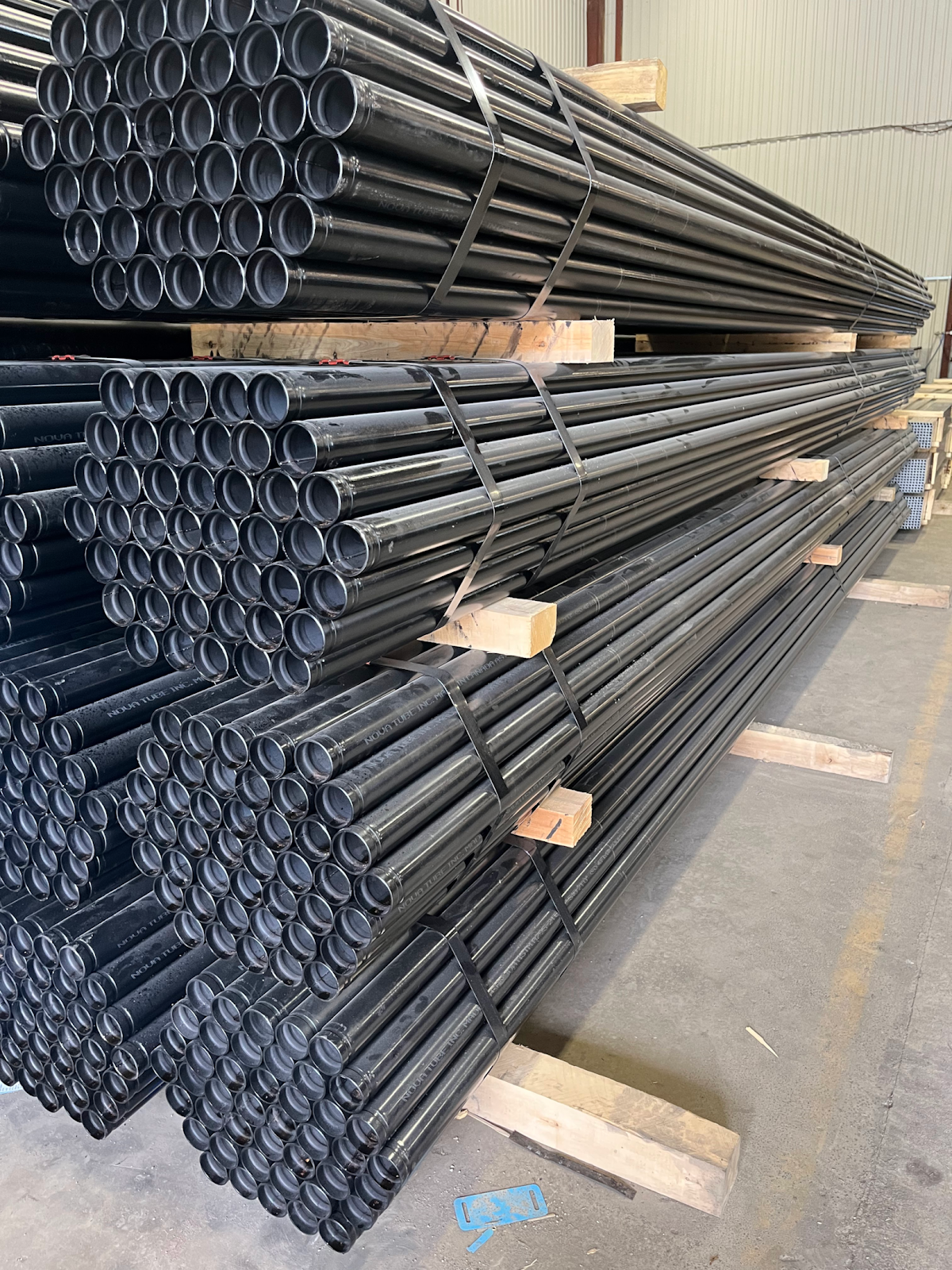

Carbon steel pipes are renowned for their strength and durability. They possess superior tensile strength, making them suitable for high-pressure applications. Carbon steel also has a high resistance to shock, a quality that other common pipe materials may lack. Additionally, their versatility makes them appropriate for various industries, including construction, plumbing, and oil and gas. Finally, carbon steel pipes are often cost-effective, offering a good balance between performance and affordability.

Disadvantages to Consider with Carbon Steel Pipes

While carbon steel pipes offer numerous advantages, there are also potential drawbacks to consider. Carbon steel is susceptible to corrosion if not properly maintained or if exposed to certain environmental conditions. Additionally, it is heavier than other materials, which could impact installation and transportation costs. Furthermore, the high carbon content makes it less ductile, meaning it has a lower ability to deform under stress without breaking. Despite these challenges, proper installation, maintenance, and use can mitigate these issues.