Price Range and Cost Factors for ASTM A53 Grade B Pipe

When considering the purchase of ASTM A53 Grade B (A53 Gr B) pipe, understanding the price range and associated cost factors is essential. The price of A53 Gr B pipe can vary depending on several factors, including material costs, manufacturing processes, pipe size, wall thickness, and market demand. Additionally, factors such as quantity ordered and delivery logistics may influence the overall cost.

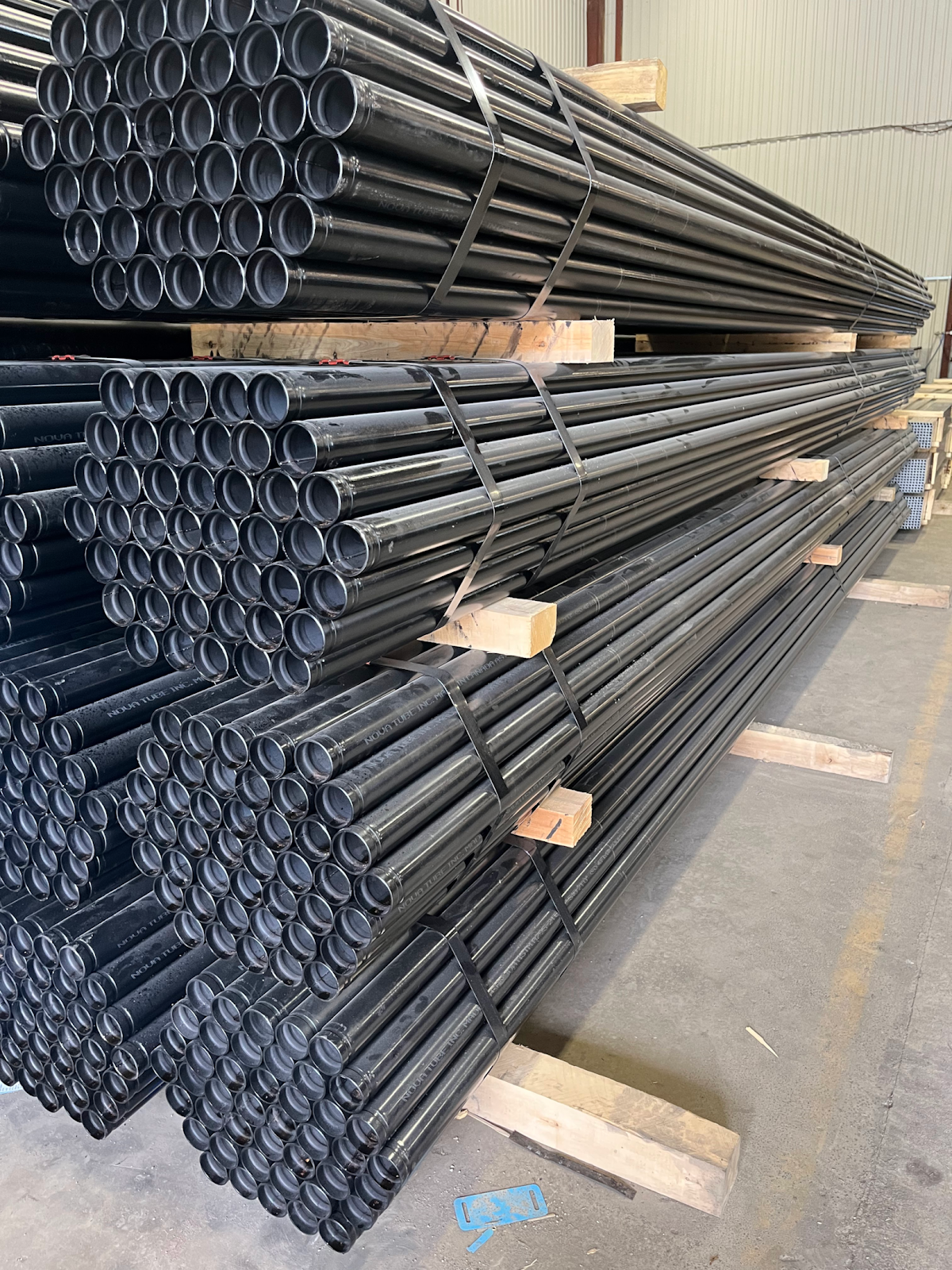

At Acier Altitube, we provide transparent pricing and work closely with our customers to offer competitive pricing that aligns with their budgetary requirements. Our pricing structure takes into account all relevant cost factors, allowing us to offer cost-effective solutions without compromising on quality or reliability. By leveraging our industry expertise and supply chain efficiencies, we strive to deliver value to our customers while meeting their specific project needs.

Understanding the Pricing of A53 Gr B Pipe

The pricing of ASTM A53 Grade B (A53 Gr B) pipe is influenced by various factors, including material costs, manufacturing processes, market demand, and overhead expenses. Material costs can fluctuate based on factors such as raw material availability and global market trends. Manufacturing processes, including welding, coating, and testing, also contribute to the final price of the pipe. Market demand and competition within the industry can affect pricing dynamics, with higher demand often leading to increased prices.

Additionally, overhead expenses such as transportation, storage, and administrative costs may be factored into the overall pricing structure. At Acier Altitube, we aim to offer competitive pricing for our A53 Gr B pipes, considering all relevant cost factors to provide our customers with value for their investment. Our transparent pricing approach ensures clarity and fairness in every transaction, allowing our customers to make informed decisions.